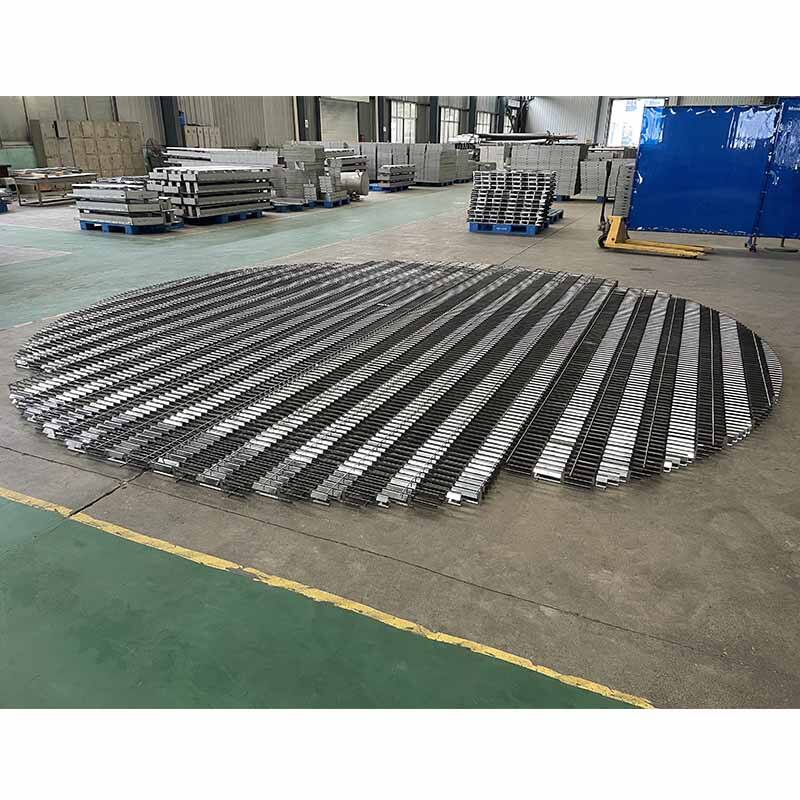

Structured packings are however important to facilitate the design of compact columns in space limited plants. In today's industrial operations where space is frequently a luxury, proper structured packings can make all the difference when it comes to efficiency and productivity.

Where can we get high performance structured packings for small plant layouts

When it comes to sourcing high-quality structured packings for small plant layouts, Sutong is a trusted supplier. With years of experience in the industrial manufacturing industry, Sutong knows what modern plants need. Our team is committed to providing engineered products that allow customers to capitalize on their investment. Weather you're a small plant or large industrial operation, Sutong has a matching solution for your unique needs.

Why structured packaging is critical for Leave

Packed columns Due to their ability to maximize the surface area in contact and enhance mass transfer, structured packings are crucial for reducing reactor size in up-to-date factories. Ultimately, plants can make a more efficient separation in less space by inserting structured packings as internals into their columns. This is crucial in space constrained plants and where the actual area matters. Sutong's structured packing is made with high quality and made according to rigorous standards to provide the best performance in a compact column.

Find out why your wholesale system needs structured packings

Wholesale operations rarely provide ample space, so it’s essential to keep equipment and machinery running as efficiently as possible. Sutong and other makes of structured packing are an excellent choice to underpin compact column design in space-constrained plants. These packings are particularly designed to provide the largest possible surface area contact for good exchange between the gas and liquid phases making separation more efficient.

Are structured packings the answer for manufacturing plants with limited space

Space constraints are frequently a challenge for production facilities. The use of stainless steel metal rings in compact column designs can provide an ideal answer to this. High capacity and efficiency than random packings give structured packings advantage in confined plant spaces. And due to the structured packings from Sutong, a better separation performance within minimized dimensions is realised in production facilities.

Pros of using structured packing in small designs

There are a lot of benefits in using structured packings with a compact design for manufacturing plants. Its efficiency and performance in separation processes are one of the major advantages. This type of nozzle ballast also offers a more efficient gas-liquid contacting due to its larger contact area. Furthermore, the structured packings are characterized by a high capacity and can thus accommodate increased throughput in less space. This may result in a cost saving for manufacturing facilities due to decreased requirement of additional equipment or expansions.

Table of Contents

- Where can we get high performance structured packings for small plant layouts

- Why structured packaging is critical for Leave

- Find out why your wholesale system needs structured packings

- Are structured packings the answer for manufacturing plants with limited space

- Pros of using structured packing in small designs

EN

EN

AR

AR

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

KO

KO

JA

JA

PL

PL

RU

RU

ES

ES

TL

TL

UK

UK

TR

TR

TH

TH

MS

MS

BE

BE

LO

LO

EO

EO

FA

FA

VI

VI

LT

LT

IW

IW

EL

EL

CS

CS

RO

RO

PT

PT

NO

NO

HI

HI

DA

DA

HR

HR

BG

BG

ID

ID

SR

SR

SL

SL

SK

SK

HU

HU

GL

GL

GA

GA