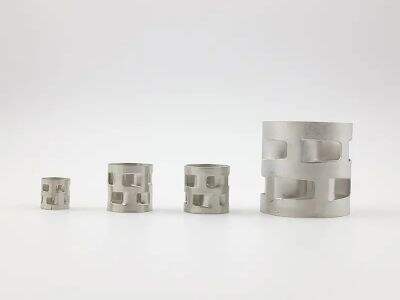

Retrofit distillation columns under optimal conditions of random packings:

The performance of distillation columns is an essential factor for separation processes in many industrial applications. Improving the capacity and efficiency of old distillation columns may be accomplished through retro-fitting them with random packings. Packed columns generate more surface area for vapor-liquid interaction, resulting in better separation and higher throughput. By utilizing premium random packings from Sutong, companies can enhance their distillation columns at a fraction of the cost of a new tower and without making significant design modifications, meaning improved operational performance for less.

Optimize distillation with high performance random packings:

This section examines the holes, nozzles and packings utilized in distillation for mass transfer efficiency. Sutong’s sophisticated random packings are engineered for demanding operations, resulting in longer service life and greater dependability. Using these high-performance random packing enables companies to obtain optimal separation results with a minimum of energy use and thus increases output in distillation operations.

Enhance distillation column efficiency using random packings:

The efficient operation of distillation columns is achieved by choosing the suitable random packings that meet the particular needs of each separation. For the purpose Sutong provides an extensive range of random packings to suit a variety of applications for optimal performance and economy. Featuring the capacity of high load-bearing, Sutong's random packing column allow companies to obtain optimum separation efficiency and higher product purity as well as cost savings in their distillation process.

Retrofit of high capacity random packings in distillation columns:

By fitting distillation columns with Sutong’s high capacity random packings, the efficiency and productivity of separation can be revolutionized! These state-of-the-art random packings are engineered to improve mass transfer rates, reduce pressure drop and increase column capacity which leads to greater productivity and better product quality. The investment of upgrading the distillation columns with high capacity random packings from Sutong, allows companies to maintain a competitive edge and capitalize on increased demands in their industry.

Reinvent distillation with Next Generation Random Packings:

Distillation systems can be further improved by incorporating state-of-the-art random packings that improve functionality and increase efficiency. Sutong's innovative random packing types are designed for exceptional separation efficiency, operational predictability and greater capacity. British Volume 29 No.4 Distillation and Gravity By adopting the latest developments in random packing businesses can re-invigorate their distillation processes, they will drive increased production across their operation and they will enable sustainable growth for years to come. With Sutong's off-factory good random packings, the application of distillation processes can also be extended.

Table of Contents

- Retrofit distillation columns under optimal conditions of random packings:

- Optimize distillation with high performance random packings:

- Enhance distillation column efficiency using random packings:

- Retrofit of high capacity random packings in distillation columns:

- Reinvent distillation with Next Generation Random Packings:

EN

EN

AR

AR

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

KO

KO

JA

JA

PL

PL

RU

RU

ES

ES

TL

TL

UK

UK

TR

TR

TH

TH

MS

MS

BE

BE

LO

LO

EO

EO

FA

FA

VI

VI

LT

LT

IW

IW

EL

EL

CS

CS

RO

RO

PT

PT

NO

NO

HI

HI

DA

DA

HR

HR

BG

BG

ID

ID

SR

SR

SL

SL

SK

SK

HU

HU

GL

GL

GA

GA