-

+86-18252065052

-

Centralized Industrial Zone TongZhou-JiangSu, China

-

Mon - Sat 8.00 - 18.00

Sunday Closed

Nantong Sutong Separation Technology Co., Ltd

Centralized Industrial Zone TongZhou-JiangSu, China

Sunday Closed

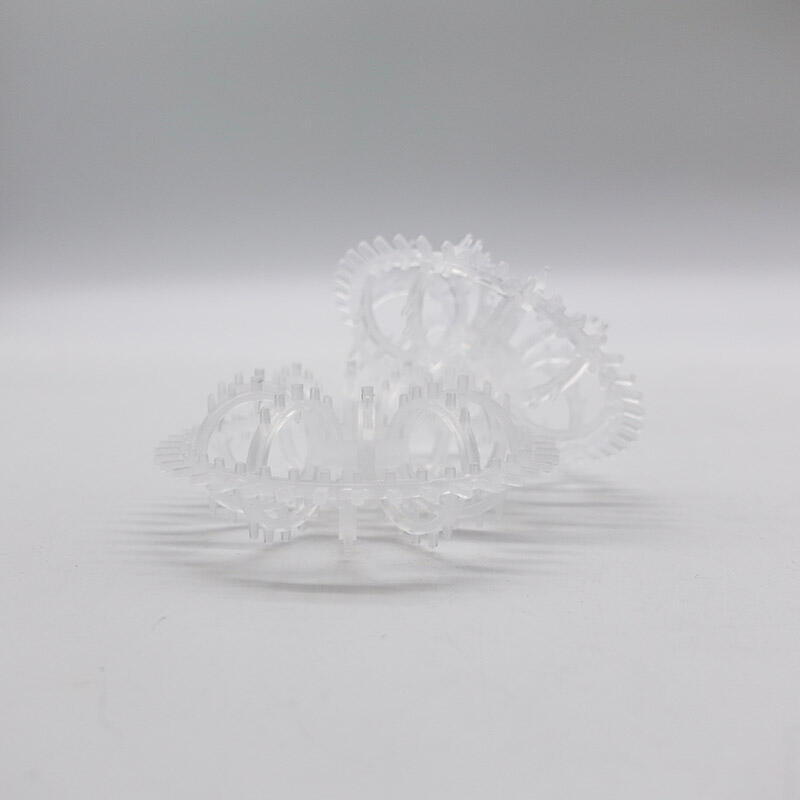

Ever wondered what your favourite refreshing drink such as soda or juice is made of? One key way to make these drinks is a process called distillation. This method allows various types of liquids to be separated according to the temperature they reach when boiling. A type of distillation that is employed in the factories is known as the sieve plate distillation. This technique works by separating liquids very effectively using small holes on special plates.

Sieve plate distillation is when two or more liquids are heated and combined, and as a result become a vapor (gas). The vapor passes upward through a tall column inside of which are sieve plates. These plates have tiny holes that allow the vapor to pass through, while trapping any liquid that has not turned to gas. The vapor cools as it rises and becomes liquid again. This contributes to splitting tracks of the original mix with interleaved dependence on their hotness.

There are a multitude of applications for which sieve-plate distillation is appropriate. One big reason for that is that it’s better at separating liquids than other methods are. The sieve plates introduce multiple stages of distillation in a single column, resulting in an economy of the process. Sieve plate distillation can also be operated continuously for long periods of time, a serious advantage in a factory situation.

Another advantage is that is capable of separation of various types of liquids. Simple combinations like alcohol and water can be separated, as well as more complex mixes in the chemical industry. This makes it very suitable for numerous factories.

Sieve plate distillation is awesome but I think having access to other processes is important. Bubble cap distillation, using caps with bubbling holes, is also a common process. It might be slower, but it provides better control. The other is simple distillation and is effective for separating liquids with a big range of boiling points.

Copyright © Nantong Sutong Separation Technology Co., Ltd 2023. All Rights Reserved.