A destillációs torna töltése nagyon fontos, függetlenül attól, hogy hűtött vízbeli üvegből vagy egy ízesített gyümölcslében dolgozik-e. Ez a cikk bemutatja a destillációs torna töltésének típusait és alkalmazásait.

MI AZ A DESTILLÁCIÓS TORNA TÖLTÉSE A KÉMIAI MŰSZAKBAN?

Destilláció Belső részek segítségével szét lehet választani egy keverék komponenseit a komponensek különböző forrás-hőmérséklete alapján. Folyamatosan használnak olajfeldolgozásra, kémiai anyagok előállítására, élelmiszer- és italiparban, más iparágakban is. A destillációs torna tartalma méretben és alakban térjen el, ami csökkenti a szükséges időt a szétválasztásra.

Töltésianyagok típusai

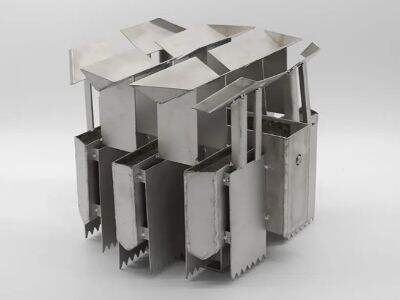

Megjegyzés: A destillációs tornák közös anyagai Egy tipikus típusú töltés a szerkezetes töltés. Ez rétegeket alkot lapokból, amelyeket bizonyos szintre hajítanak, hogy nagy felületet kapjanak jobb szétválasztás érdekében. Egy másik forma, a véletlenszerű töltés, amikor kis elemeket, kerámiatekat, fémeket, plasztikát vagy mást rögzítenek véletlenszerűen a tornában.

Csomagolási típus kiválasztása

Vegye figyelembe, hogy mennyi elválasztást kell, és mennyi nyomást tud egy anyagfajta kiállni a csomagolási típus kiválasztásakor a destillációs műveletéhez. A magas hatékonyság és alacsony folyadék-tartalom a strukturált csomagolással kapcsolódik legjobban. Ellenben, Véletlenszerű tömörítés azonnál inkább alkalmas, ahol nagy kapacitás és rugalmasság szükséges. Egy szakszervezettel való beszélgetés segít megtalálni a legjobb csomagolási típust önnek.

A hatékonyság maximalizálása

Jó destillációs torna csomagolása elengedhetetlen a jobb folyamat-hatékonyság érdekében alacsonyabb energolfelhasználással. Léteznek módok a destillációs torna teljesítményének javítására a megfelelő csomagolási anyag és tervezés alkalmazásával. Továbbá, a csomagolási anyagok folyamatos figyelése és karbantartása integrális része annak, hogy biztosítani lehessen a szilárd működést és elkerülhetők legyenek a komplikációk.

A csomagolási típusok alkalmazásai

A szerkezett tömörítés gyakran használatos rafinálókban és kémiai üzemekben a nyersolaj komponenseinek elválasztására. A kémiai feldolgozás véletlenszerűen tömörített anyagokat használ az eltérő kémiai összetevők elválasztására. Mindkét típusú tömörítés rendkívül hasznos a destillációs tornyokban, és biztosítják, hogy az elválasztás hatékonyan történjen több iparágban is.

Összefoglalva: Strukturált töltések fontos szerepet játszik számos olyan iparágban, amelynek komponensek elválasztására van szüksége a minőségi termékek előállításához. Azt megértve, hogy vannak különböző típusú tömörítési anyagok, valamint néhány előnük és hátrányaik is, segíthet abban, hogy jobb tömörítési anyag-választást tegyen a destillációja érdekében. Tömörítési szabály: Válassza ki a megfelelő tömörítési típust, és helyesen osztson el azt.

EN

EN

AR

AR

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

KO

KO

JA

JA

PL

PL

RU

RU

ES

ES

TL

TL

UK

UK

TR

TR

TH

TH

MS

MS

BE

BE

LO

LO

EO

EO

FA

FA

VI

VI

LT

LT

IW

IW

EL

EL

CS

CS

RO

RO

PT

PT

NO

NO

HI

HI

DA

DA

HR

HR

BG

BG

ID

ID

SR

SR

SL

SL

SK

SK

HU

HU

GL

GL

GA

GA