Distillation towers packing selection is highly crucial. It allows the towers to function better, and more efficiently. The substances that reside within inside the tower are responsible for keeping various liquids apart and ensuring their purity. Should incorrect materials are used, the tower may not function as designed, and the liquids will not separate properly. This is why the distillation towers at Sutong demand the right packing materials.

The Importance of Choosing the Right Packing Materials

The decision of which packing materials to use for distillation towers is a critical factor in ensuring good tower performance. The packing material is designed to expose more surface area to the liquids that flow through the tower. That means the different liquids are able to separate more easily. The liquids may not separate in the right way if the packing materials aren’t well suited to the tower, which ultimately means there are lower quality products. That is why choosing the best Structured Packings materials for distillation towers in Sutong is essential.

Considerations When Selecting Packing Materials

When selecting packing materials for distillation towers, there are several critical factors to consider. One aspect is tower size, larger sized towers require more material to be effective. The other is the type of liquid separation – some liquids need special materials to separate properly. We also need cast concerns to the temperature and pressure in the tower, as this will influence the effectiveness of the packing materials. By considering these factors, Sutong can help ensure that their distillation towers are functioning at their best.

Packing Materials: There are Different Types

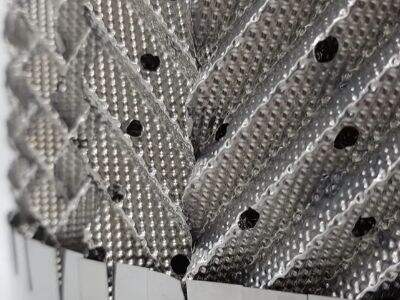

There are several types of packing used in the distillation towers. The various types include structured packing, random packing, and trays, etc. Structured packing is formed of layers arranged in a particular manner, which increases the surface area. Random packing is created from materials added into the tower at random to aid liquid(s) separation. Trays are flat surfaces that support the liquids and allow them to separate as they trickle through the tower. Different distillation methods benefit from different types of packing materials for the right reasons. Sutong can increase the efficiency of their distillation towers by choosing the correct Random Packings material.

Choosing the Right Packing Materials— A Short Guide

To ensure distillation towers have optimal performance, selection of proper packing materials is essential. One piece of advice is to consider how the Packings materials will interact with the separated liquids. Using corrosion- and chemical-resistant materials could make the tower last longer. Also another tip that we hope you will do, with this another tip you should choose packing materials that can provide a high surface area, in order to make easier separation between liquid. Spraying and replacing the packing materials regularly would help the tower work fine. Use these tips to help Sutong optimize their distillation towers.

Packing Materials in Distillation

Packing materials play a crucial role in the distillation step, allowing for the simple separation of multiple liquids. The materials provide a large surface area, enabling the liquids to interact and separate more effectively. You need to consider factors like your tower size, the type of liquid you are handling, temperature, and pressure to choose the right packing. Therefore, right choice of materials for distillation towers at Sutong can ensure smooth runnings of the company's processes and quality products.

EN

EN

AR

AR

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

KO

KO

JA

JA

PL

PL

RU

RU

ES

ES

TL

TL

UK

UK

TR

TR

TH

TH

MS

MS

BE

BE

LO

LO

EO

EO

FA

FA

VI

VI

LT

LT

IW

IW

EL

EL

CS

CS

RO

RO

PT

PT

NO

NO

HI

HI

DA

DA

HR

HR

BG

BG

ID

ID

SR

SR

SL

SL

SK

SK

HU

HU

GL

GL

GA

GA