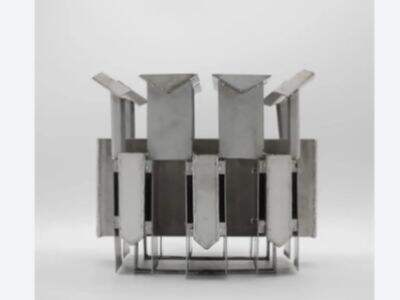

Liquid distributors are critical to well-performing columns. They do the job of ensuring that the liquid gets passed around evenly so everything works. So, some of this ways could make the column to job well and how liquid distributors can help?

The role of liquid distributors and how they help improve column performance

As liquid distributors; they perform very similar to traffic directors of a busy city. They control the liquid flow so that it all goes through the system as planned. The brake fluid does one job, the radiator does another along with the oil, power steering etc… They act like traffic lights to direct the flow of liquid. For columns this is significant and makes it work powerfully.

Uniform Liquid Distribution in Columns for Optimum Mass Transfer

Even dispersion of liquid in a column assists in mass transfer. Mass transfer is a lot like playing with toys when you were young: everyone should have their turn. It properly spreads the liquid on all the different parts of the column to make sure that none of it is missing, and by doing so ensures everything is working in harmony together. This helps the column in performing its functionality efficiently and completes that task faster.

Significance of liquid distributors having good design and proper installation to achieve highest column efficiency

As with creating a solid block tower, columns have to be formed and positioned the right way in order for them to function correctly. The liquid distribution must be adequately placed and is made from appropriate material such that it can carry out its work effectively. The liquid distributor in distillation column can lead to issues with the column performance, if not properly designed/executed. It is important to perform everything properly for great results.

The Role of Liquid Distributors in Preventing Channeling and Maintaining Even Flow Through Columns

Example: when water in a river only seems to flow in one direction, this flows as 'channeling. Same for liquid in columns if it is not theory uniform. This is where liquid distributors come in as they ensure that the liquid is spread out uniformly. This means the flow in columns remains rate-controlled and all is good. Liquid random distributors ensure the spongy flows of a column by preventing channeling.

Optimising liquid distribution strategy to improve column results

Having a good liquid distribution for optimal columns performance It involves the application of correct liquid distributors and their exact positioning. That is what works, so it ensures that the columns perform as well as possible and get the job done for you. This shall reduce the wastage of time and resources thereby facilitating a smooth process.

This is the end of fluid distributors. The liquid distributor are key components in ensuring that columns can work well. Columns can reach their full potential by appreciating the significance of these five key elements: uniform liquid distribution, proper design and installation, channeling prevention, treating columns as a set, and employing better delivery strategies.

Table of Contents

- The role of liquid distributors and how they help improve column performance

- Uniform Liquid Distribution in Columns for Optimum Mass Transfer

- Significance of liquid distributors having good design and proper installation to achieve highest column efficiency

- The Role of Liquid Distributors in Preventing Channeling and Maintaining Even Flow Through Columns

- Optimising liquid distribution strategy to improve column results

EN

EN

AR

AR

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

KO

KO

JA

JA

PL

PL

RU

RU

ES

ES

TL

TL

UK

UK

TR

TR

TH

TH

MS

MS

BE

BE

LO

LO

EO

EO

FA

FA

VI

VI

LT

LT

IW

IW

EL

EL

CS

CS

RO

RO

PT

PT

NO

NO

HI

HI

DA

DA

HR

HR

BG

BG

ID

ID

SR

SR

SL

SL

SK

SK

HU

HU

GL

GL

GA

GA