This Article includes :Benefits of employing demisters in gas processing/demister theory of operation/Demister helps to improve efficiency and protect delicate pieces/and how the lifeguard maintains optimum performance and reliability as well as its types involved Application for gas processing operations.

Advantages to using demisters in gas processing applications

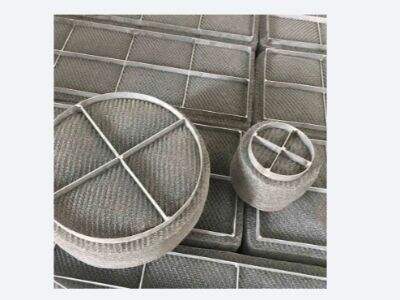

There are many advantages to using demisters in gas processing applications. Demisters are special devices which help to remove liquid droplets from a gas flow or stream and thus assist the processing equipment to work more efficiently. The demister pad are designed to eliminate this droplets which if left alone for long can damage the unit, obstruct or hinder operation, hence leading to costly maintenance and downtime. The practical use of these types of demisters are to ensure that gas processing operations can be carried out as effectively and efficiently as possible which will result in cost savings and improved productivity.

Improved efficiency using demisters

Improved efficiency using demisters is yet another crucial benefit. This entrainment free liquid removal is vital to the performance on high value gas processing equipment. The demister cut operating costs — in some cases by half — and are cost-effective solutions to improving efficiency. The more effectively equipment is performing, the higher quality products that can be produced in less time – and this equals profits.

Gas Processing Requires Equipment Protected with Demisting Technology When gas streams contain liquid droplets, the equipment can be damaged and corroded, which will require expensive repairs or replacements. This type of damage could be prevented by capturing the droplets before they reach the equipment, and demisters do that. Demisters can help companies reduce chances of unexpected downtimes by avoiding damage to their equipment and keeping things under control.

Another fundamental aim is to obtain optimal performance and reliability

Aside from the operational considerations associated with demisters for gas processing facilities, another fundamental aim is to obtain optimal performance and reliability. Equipment can be kept operating at its peak performance when free of liquid droplets with the use of pad demister. Ultimately, this helps companies optimize performance and meet production targets with less downtime. All organisations would prefer that its equipment is performing efficiently, without any downtime or failures to prevent expensive holdups and ensure customer satisfaction.

Demisters play an integral role in helping gas streams

In gas processing operations, demisters have a crucial function to play. Demisters play an integral role in helping gas streams to be free of liquid droplets because those droplets can have consequences for the quality and effectiveness of processing operations. Demisters remove these droplets, ensuring the equipment operates smoothly and efficiently.

To summarize, demisters can be very useful to enhance process efficiency and equipment reliability in gas separation processes. Companies will improve their efficiency, protect equipment, maximise the performance and reliability of their facilities with demisters and can take benefit for better overall gas processing operations.

EN

EN

AR

AR

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

KO

KO

JA

JA

PL

PL

RU

RU

ES

ES

TL

TL

UK

UK

TR

TR

TH

TH

MS

MS

BE

BE

LO

LO

EO

EO

FA

FA

VI

VI

LT

LT

IW

IW

EL

EL

CS

CS

RO

RO

PT

PT

NO

NO

HI

HI

DA

DA

HR

HR

BG

BG

ID

ID

SR

SR

SL

SL

SK

SK

HU

HU

GL

GL

GA

GA