Making liquefied natural gas, or LNG, for example is all about splitting up different parts of the gas. This step must be quick and extremely good at sorting similar words apart. But sometimes the region in which it happens is very small, so there’s little room to accommodate large equipment. At Sutong, we have a solution to this problem that we call structured packings. These packings are very good in separating gases, even with not much space. They are unique inside the machines and help ensure that the gas is clean and ready to use. This article discusses how these packings perform in cramped quarters, but also why they are terrific for big jobs as well

Structured Packings For Compact Units

It’s a tricky calculus to make when space is tight for L.N.G. plants. Those provided by Sutong for structured packings help, since they work better in tight spots than typical solutions. Imagine a building with countless floors. If you want to cram in a lot of people, you also need intelligent designs that don’t take up much room, such as elevators and stairs. Structured packings behave as these clever devices inside the gas machines. They have layering and shaping that enables gas and liquid to flow through quickly, and separate well. More significantly, that means the machines can be smaller and still get the job done faster and cleaner. This reduces the cost and also space requirement in plant

Another big advantage is the way these packings respond to varying gas quantities. At large LNG plants, gas is constantly flowing. The packings can handle it without cracking or freezing up. They are less likely to get clogged, so there is less fussing and cleaning. For instance, in the case of small LNG facilities that are space-constrained, old tools may take up too much space to function properly. But Sutong’s structured packings can do the same work in a smaller machine, saving space and energy. This is significant because constructing big plants can be expensive, and occasionally land may be scarce

In addition to saving space and functioning efficiently, these packings contribute to cleaning the LNG. Cleaner L.N.G. is better burning and safer to store and use. Structured packings offer more surface area inside the machine, and therefore the gas and liquid have more opportunities to interact and separate properly. That is, less waste and better quality. Companies that run LNG plants really love these packings because they prevent problems and keep the plant running. Like a toy that can be crammed into a tiny box yet still do all the neat stuff bigger toys do

Why is Structured Packing Well Suited for High Capacity LNG Trains in a Small Footprint

Sure, that busy highway still exists but now you’re crammed with the rest of the cars on a much smaller road. You want a clever way to make traffic move quickly without crashes. Structured packings are analogous to that smart road in LNG appliances. When large amounts of gas are moving fast, such packing can help spread it out without slowing it down or getting in the way. Sutong’s results suggest that structured packings process large gas flows more effectively than older methods. The design channels gas uniformly and allows liquid to spread thinly, causing the divorce of components to be faster and more complete

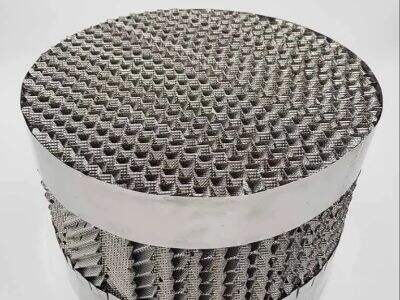

There is a reason these packings work so well, and that has to do with their shape. They are prepared using thin sheets wrapped in special patterns. Those patterns make a lot of little channels for gas and liquid to flow through. This definition has the effect of increasing contact bet- ween gas and liquid, assisting in rapid separation. Even though it’s a small machine that still can process a large quantity of gas without loosing its quality. For instance, in a high-capacity LNG unit that transports or processes thousands of cubic meters through every hour, this packing keeps things moving without blockages or damage

In addition, the structured packings from Sutong are constructed from durable materials with a long life. Even under harsh conditions, such as cold and high pressure, they don’t wear out quickly. This matters because the time and expense of fixing or altering a component inside an LNG plant are enormous. So having packings that last a long time enables the plants to keep running. A further object is to minimize error during separation by such packings. “Less error means safer gas and less likelihood of an accident. Workers rest easier knowing that relied-upon equipment is working out

Squeezing these packings into a small space can seem difficult, but Sutong’s engineering team makes it work. Custom shapes and sizes see to it that your packings take up the space they need and no more. This allows plants to maximize their investment in equipment. Finally, structured packings are not simply parts inside a piece of equipment; they are intelligent solutions that solve tangible problems in LNG plants where space and quality make a big difference

What are the main advantages of structured packings for LNG process separation

In the world of Liquification of natural gas (LNG), it is critical to separate different components in an efficient and careful manner. This is a process that makes sure it’s clean of pollution or something that will make the gas unsafe to use. Structured Packings One of the separation aids which is found to be useful in this process is structured packings. Packed tections are special materials. In that process the material used still as how the highest separation efficiency stored. Such packings are of special construction and provide a smooth flow through gas and liquid. They have a shape and configuration that gives them a large surface area over which gas and liquid can meet. This helps the separation work better

The advantage for structured packings is that the gas separation efficiency can at least be improved. This results in a purer LNG product and compliance with stringent quality regulations. Another advantage is that structured packings are all about saving energy. The mix separates more easily, so the equipment doesn't have to work as hard, resulting in reduced energy consumption. The former is good for the environment, and for companies that seek to tamp down costs

The structured packings are also very pliable. They can be constructed of various materials according to the conditions inside the LNG units, such as high pressure or extremely cold temperatures. And because they are more pliant, they last longer and require fewer repairs. They are also lightweight, and occupy less space than previous methods. This is particularly vital when constructing LNG plants with constraints of area

Our Structure Packings Applied in LNG Separation Sutong offers quality structured packings specially used for separation in LNG refining system. Sutong's packings are manufactured with the most current technology to guarantee impeccable performance. By selecting Sutong’s product, the LNG plants can have cleaner gas and less energy consumption with longer-lasting equipment. These advantages enable LNG companies to operate more efficiently and safely while saving money

Where to Source Quality Wholesale Suppliers of Structured Packings for LNG processing

When LNG companies require structured packings for separation, they need to have someone they can rely on a supplier that can deliver their performance-critical products on time. A professional wholesaler should provide high quality, strong products that match the stringent requirements of LNG works. It would also be necessary for the supplier to offer packings in quantities enough and time wise to cope with requirements of big LNG plants

Sutong is a recognized name in LNG structured packings. With many years experience of producing and selling packings which are good at corrosive conditions. Customers can trust Sutong to produce quality products in safe, clean, and efficient facilities. LNG separation is exacting work, so selecting a supplier such as Sutong will ensure that problems and uncertainties are avoided

Another important factor from finding a wholesale supplier is the availability of technical support. LNG projects frequently require a consultant to select the correct kind of packing, and to install it properly. Sutong’s technical team will be available to help customers with professional advices from the beginning to end. This support means that LNG plants can achieve the optimum performance from their separation facilities

Suppliers including Sutong also allow you to choose your delivery window. There's often a tight schedule for LNG projects, so being able to get the packings when needed is critical. Sutong gets that, and works through and around them to ensure deadlines are met, constraints work for him. Such reliability allows LNG companies to minimize expensive downtime and continue production

To sum it up, LNG producers seeking manufactured packings should look to a vendor with quality, expertise, and reliable service. Sutong fulfills all these requirements and is a reliable associate over the long term for the LNG business. For cooperation with Sutong, LNG plants will get confidence that they are equipped to perform efficient and safe separation of gas

How Structure Packings Solve Space and Performance Limitation of Current LNG Units

Commercializing new LNG facilities is tough and two of the toughest issues are finding enough room and achieving high performance. Liquefied natural gas plants are frequently designed to involve squeezing complex machinery into tight spaces, particularly when constructed near cities or on offshore platforms. At the same time, these plants have to do a good job of stripping natural gas out for clean LNG that meets stringent quality regulations. Structured packings are a clever way to solve of both problems

One of the ways that structured packings help with space is by being compact. Whereas older separation materials may be large and heavy, structured packings are meant to occupy less space inside the separation towers. Their unique appearance allows for tight packing and a large specific surface area for gas/liquid contact. That means the LNG units can be smaller and lighter, but still work a treat

Freeing up space for LNG plants allows them to have smaller footprints, which can lower construction costs and make maintaining the plant simpler. It is easier to handle smaller units and relatively little support equipment is required. This is particularly useful for LNG plants located in remote or congested areas and land values are at a premium

Structured packing also enhances performance by giving better contact between the gas and liquid phases. This results in a better separation and hence a better LNG product. The better the separation, the less energy plants consume and the more smoothly they run. Meanwhile, this helps to keep operational costs down and minimizes the environmental impact

Sutong’s packings are designed specifically designed to fit the specific requirements of today’s LNG train. They are compact in design and they deliver consistent separation efficiency. Sutong’s offerings allow LNG plants to work in harsh conditions without trading off performance. Our packings also provide a longer service life that eliminates the need for replacements and maintenance, additional savings in the long run

Custom or modularized? Structured packings are an intelligent answer for today’s LNG units, because millimetres count and more efficiency is not enough. By selecting Sutong’s high efficiency packings, LNG operators can meet the challenges of space and performance. The result is safer, cleaner and less expensive LNG production, which is good for business and the environment

Table of Contents

- Structured Packings For Compact Units

- Why is Structured Packing Well Suited for High Capacity LNG Trains in a Small Footprint

- What are the main advantages of structured packings for LNG process separation

- Where to Source Quality Wholesale Suppliers of Structured Packings for LNG processing

- How Structure Packings Solve Space and Performance Limitation of Current LNG Units

EN

EN

AR

AR

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

KO

KO

JA

JA

PL

PL

RU

RU

ES

ES

TL

TL

UK

UK

TR

TR

TH

TH

MS

MS

BE

BE

LO

LO

EO

EO

FA

FA

VI

VI

LT

LT

IW

IW

EL

EL

CS

CS

RO

RO

PT

PT

NO

NO

HI

HI

DA

DA

HR

HR

BG

BG

ID

ID

SR

SR

SL

SL

SK

SK

HU

HU

GL

GL

GA

GA