Those systems that collect vapor fast mist eliminators play very crucial roles. When the vapor moves quickly, little water droplets or liquid particles can become stirred in. These droplets dirty the vapor, which is a concern if that’s supposed to be pure vapor for industrial use. These droplets are captured by the mist eliminators and prevented from being emitted into the environment. They also, though, help to keep the vapor clean doing so. At Sutong, we ensure the better performance for these systems even during challenging times Is this process is followed? We all know that when it comes to high-speed vapor recovery, the right equipment makes it easier to stop trouble before it begins. Mist eliminators are more than filters; they act as vapor police in high-velocity systems.

Where to Get Wholesale Mist Eliminators for Industrial Vapor Purity Solutions

Good quality mist eliminator at wholesale pricing can save money and prolong the life of your system. Sutong offers a variety of mist eliminators for all kinds of industrial vapor recovery systems. Our product is durable enough to withstand fast vapor flow and capture the smallest droplets. Quality and strength should be inspected while searching for a wholesale mist eliminator. It may be more expensive to do so in the long run due to parts wearing out quickly, or not functioning properly. If, for instance, a mist eliminator fails while in operation, the vapor will bring undesired liquid with it resulting in damage or pollution. At Sutong, we ensure all our pieces are strong, well-made and tested before it ships. In order to get better price and fast delivery, you can bulk buy from us. And we offer assistance with finding the correct size and type for your system. Some companies offer only one type, but Sutong has different models that suit quite a few purposes. This flexibility makes it easy for customers to pinpoint exactly what they need without paying for unnecessary features. Additionally our staff is prepared to answer any installation questions or concerns. Our wholesale approach means you stock up for emergencies or long projects and with Sutong, you don’t have to worry about getting your vapor big but keeping it pure.

Typical Mist Eliminator Problems And How To Sustain Best Vapor Purity

Mist eliminators perform a dirty job, however and all too frequently something goes awry that hampers their mission to keep vapor pure. One common issue is clogging. If the mist eliminator accumulates too many droplets or dirt, it becomes blocked. This slows the vapor rate and decrease the system efficiency. Another problem is corrosion. Mist eliminators are liquid and vapor systems, so some components will rust or wear off if they are not made of the proper materials. If one of these mist eliminators cracks or breaks, the droplets will pass through and reduce vapor purity. At Sutong, we have witnessed these kinds of issues many times and we know how to solve (or prevent) them. Regular cleaning is very important. Rinsing the mist eliminator with water or cleaning solution dislodges particles. And inspecting for damage or rust ahead of time can save time and money before the problem gets worse. Some of the time, you’re better off replacing a part early even if it’s not fully worn down yet. Placement also counts: if the mist eliminator isn’t installed just so, it can miss out on some droplets. Our experience demonstrates that operators with the ability to identify early warning signs translates into longer system life. In high-speed recovery systems, mist eliminator should be checked frequently because what begins in a vapor and achieved through velocity happens very quickly. The use of vetted Sutong quality combined with regular care, maintains clean vapor and long lasting systems. With vapor, it's about not only the gear you're working with but also how well you take care of it.

Why Are Mist Eliminators so Important in High Velocity Vapour Recovery Applications?

In numerous industries, vapors are generated during various processes including, for example, during evaporation of liquids or release of gases. These gases are frequently accompanied by small liquid droplets known as mist. As the vapor moves at very high speed, as when used in high-velocity recovery systems, the mist can make a big mess. That's where mist eliminators (also called demisters) come in: they are special gadgets that trap and remove tiny liquid droplets from vapor streams. Without them the mist can be carried with the vapor and whether cause harm or pollution, or lead to poor recovery quality.

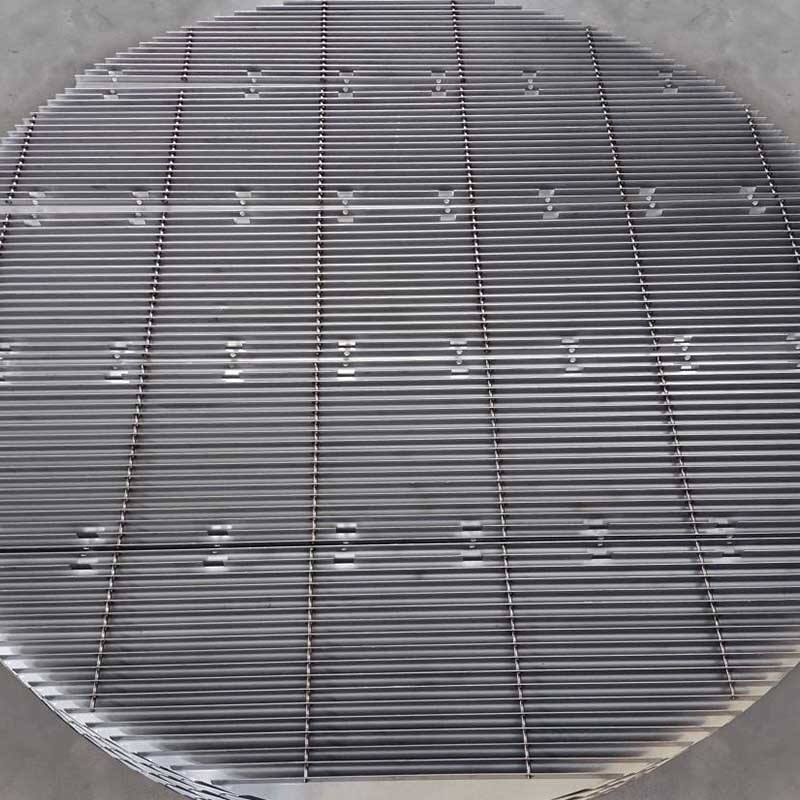

High-velocity vapor recovery systems capture vapors rapidly and direct them elsewhere, where they can be reused or otherwise dealt with. But when the vapor is traveling at high speeds, its mist droplets are forcefully propelled forward and it’s harder to pull them apart. Mist eliminators come to the rescue by slowing down the vapor or being constructed of catching the droplets. This holds true even in high-velocity vapors, one for which Sutong mist eliminators have been built to work well. They employ clever designs such as mesh pads or baffles that trap the mist droplets and make them stick to surfaces, where they drop out of the vapor stream. This prevents unnecessary liquids from entering in the vapor.

They also are important because they prevent fouling of equipment. Mist droplets can lead to rust, corrosion or clogging problems whenever they travel with vapor into machines. Sutong’s products, by clearing away the mist, also help maintain a machine longer. This translates into less repair and down time, which all cost money and man hours. Suffice it to say mist eliminators are an integral part of maintaining efficient operation for high-velocity vapor recovery systems, protecting the environment, and ensuring as pure a vapor end-product is produced.

How Can Mist Eliminators Improve Product Yield In Industrial Vapor Recovery Applications?

The quality of recovered vapor is essential in those industrial systems because it could be used again or reacted with it to create new products. In case the steam contains mist or droplets of liquid it will impair its quality and will lead to issues in the equipment which is downstream. It is also essential to have clean, pure air and in this regard, many companies employ special mist eliminators, in order to make sure that the vapor is not contaminated by any impurities. Steam, without spray, is not so bad, leaves less trouble and yields a better production.

The mist eliminators by Sutong help improve the quality of the product since the mist droplets in the vapor are almost removed. This is the reason the recovered vapour is relatively free and fewer impurities. Sam Allard Clean is used in reactions of chemicals to fuel recovery or, in fact, to produce medicines. Mist can be mixed with vapor when it is not removed, and it can create undesired chemicals and render machines less productive. This in its turn may lead to the low quality of products even to safety concerns.

It is also not the need to treat liquids within pipes and tanks as the mist droplets are removed, hence the vapor recovery system is more effective. This type of arrangement will reduce chances of leakage or blockage. The mist eliminators produced by Sutong are flexible to any kind of industrial requirements both small plants and large factories. They will even work with materials that will last long and withstand the harsh weather conditions, hence they do not need any maintenance.

Sutong mist eliminators, keeping vapor clean and dry, save money by making industries cut waste and refine finished products and guarantee that systems are safe and efficient. This shows the importance of these units to ensure good product quality in the vapor recovery systems.

What's New in Mist Eliminator Technology for Vapor Recovery

New industries are demanding the removal of mist eliminator technology which is being done at a faster and more efficient way. Sutong is determined to produce new design and use superior materials to make mist eliminator filter more efficient and more life span. To get mist eliminators effective in such fast vapor flows without causing excessive pressure drop is one large development. The pressure drop is at which the vapor releases energy in passing through the mist eliminator. The less this the better, as it is a valuable consideration in the economy of power and economy.

The other trend is using special coating and material to avoid corrosion and fouling. Vapor recovery systems do that using harsh chemicals or salty air which may corrode products. Sutong uses superior materials, which are long lasting and less demanding in terms of cleaning. This enhances the degree of reliability of the systems and, thus, the cost of their maintenance is less.

Smart technology is also penetrating mist eliminators. This can now be fitted with sensors that will help gauge the efficiency of the mist eliminator. The operators may receive notifications in real time in case the mist eliminator is clogged or worn out so that they can replace it. You do not want to gamble away a game and time of the essence.

Finally, Sutong is studying the environmentally friendly designs with a low waste and can be recycled. As industries focus more on conserving the environment, the mist eliminators must also be green. The new products that we have used have a lower material consumption, yet they are strong and functional, and therefore they enable industries to take action more in balance with nature.

In summary, the recent trends of mist eliminator focus on higher performance, increased life of the guard rails, intelligent monitoring and environmental friendliness. Sutong is still on the forefront of these innovations and with its help, businesses are able to develop and maintain their vapor recovery systems to operate cleanly, efficiently and safely.

Table of Contents

- Where to Get Wholesale Mist Eliminators for Industrial Vapor Purity Solutions

- Typical Mist Eliminator Problems And How To Sustain Best Vapor Purity

- Why Are Mist Eliminators so Important in High Velocity Vapour Recovery Applications?

- How Can Mist Eliminators Improve Product Yield In Industrial Vapor Recovery Applications?

- What's New in Mist Eliminator Technology for Vapor Recovery

EN

EN

AR

AR

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

KO

KO

JA

JA

PL

PL

RU

RU

ES

ES

TL

TL

UK

UK

TR

TR

TH

TH

MS

MS

BE

BE

LO

LO

EO

EO

FA

FA

VI

VI

LT

LT

IW

IW

EL

EL

CS

CS

RO

RO

PT

PT

NO

NO

HI

HI

DA

DA

HR

HR

BG

BG

ID

ID

SR

SR

SL

SL

SK

SK

HU

HU

GL

GL

GA

GA