-

+86-18252065052

-

Centralized Industrial Zone TongZhou-JiangSu, China

-

Mon - Sat 8.00 - 18.00

Sunday Closed

Nantong Sutong Separation Technology Co., Ltd

Centralized Industrial Zone TongZhou-JiangSu, China

Sunday Closed

Ceramic random packing is a special material used in factories to help make chemical processes work better and faster. It is shaped like a piece of a puzzle that is made for either a tower or a machine to mix and separate several liquids and gases together. Most industries that need to carry out this kind of process has been able to benefit from this material and Sutong is the ceramic random packing manufacturing company that has found advantages of it.

There are several advantages that factories could utilize if they are using 'ceramic random packing' in their machines. You learn more energy-efficient and cost-effective operations, making the machines run more efficiently. That translates to a greater number of products produced in shorter timeframes with less waste. This allows for a cleaner environment by filtering out harmful substances, hence not diffusing them into the air and water.

Ceramic random packing has excellent mixing and separation of miscible or immiscible liquids, as well as gases. These are important in sites such as oil refineries, chemical plants and water treatment facilities. When they utilized ceramic random packing in these industries, they were able to accomplish their work faster and better. That means they can safely produce more products. Sutong's ceramic random packing supports these industries to operate stable and high self.

Ceramic random packing is essential in industries that use towers to mix and separate liquids and gases. This mixing is ensured by the ceramic random packing which is used in the reactor. Significance: Sutong Products guarantees that good quality products are being made. Sutong ceramic random packing for tower improvement, thorough mixing, and a more efficient process.

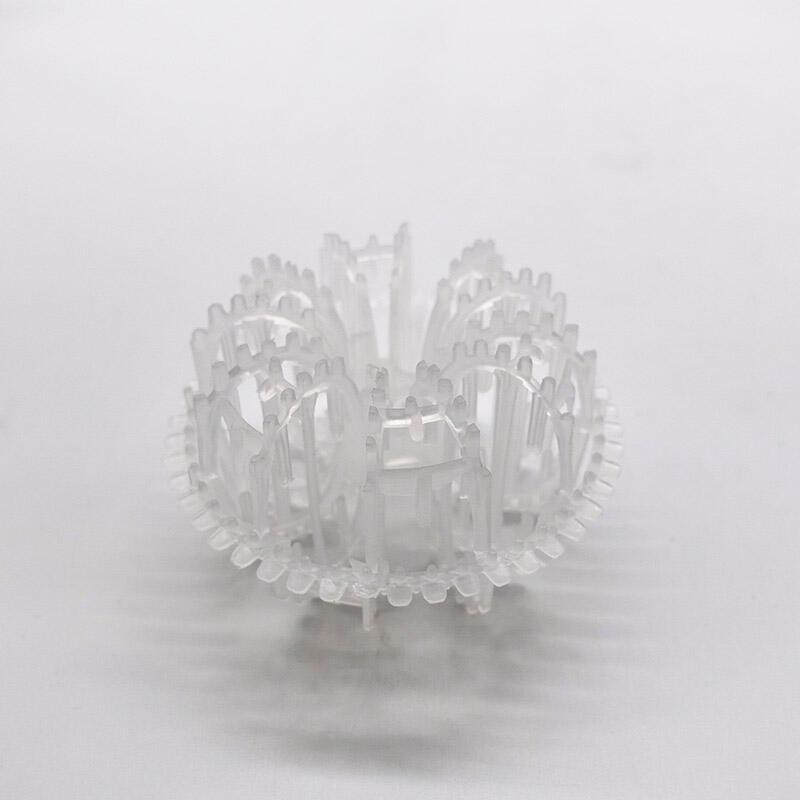

The ceramic random packing is available in a variety of shapes and sizes. Some are round, some are square and some are even star-shaped. Different shapes are built for different jobs on the machines. Sutong Random Packings is also a factor! In your initial methodology, you decide what sizes of pieces you want to cut: some machines can take smaller pieces while some can take larger pieces. Depending on the field of activity Sutong offers many shapes and sizes.

High Strength: One of the greatest features of ceramic random packing is its high strength. Which means it will stick around, even in harsh conditions. Users of Sutong's ceramic random packing can be confident that it won't break easily and won't wear out easily. That is we need these Sutong random packing, and we don’t have to spend a lot replacing it. Excellent durability of ceramic random packing is one of the reasons why Sutong is trusted by the industry.

Copyright © Nantong Sutong Separation Technology Co., Ltd 2023. All Rights Reserved.